Cost Types

- Lump Sum Costs

- General Prelim – Salaries, Facilities, Support Services

- Weighing, Load-Out and Seafastening

- Reimbursable at Man-Hour Unit Rates

- Expended Man-Hours for Engineering, Procurement

- Reimbursable at Cost

- Business Travel Expenses

- Reimbursable at Cost Plus

- Third Party Services / 3rd Party Engineering Services

- Tagged Materials / Equipment Packages

- Reimbursable at Measurement Qty Unit Rates

- Bulk Materials and Construction Labour

Project Cost Management

PROJECT COST MANAGEMENT

COMPLIANCE & RISK MANAGEMENT

TAXES

Project Planning & Control System

Work Descriptions

- SOW

- Requirements,

- Specifications

- WBS

CPM Analysis EPC

Schedule

- Master

- Detailed Plans

- Look ahead plans

Base line S curves

- Man hour

- Budget

Execution begins

- Performance Tracking

- Work Progress

- Cost Committed & Expended

- Performance review

- Performance variances - time, cost

- Trends/ forecast

- Management Decisions

- GO/NOGO

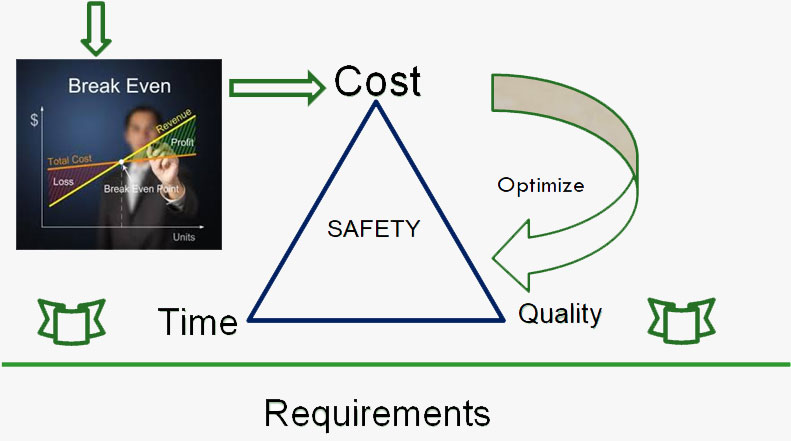

Goals & Objectives

- Project

- Corporate

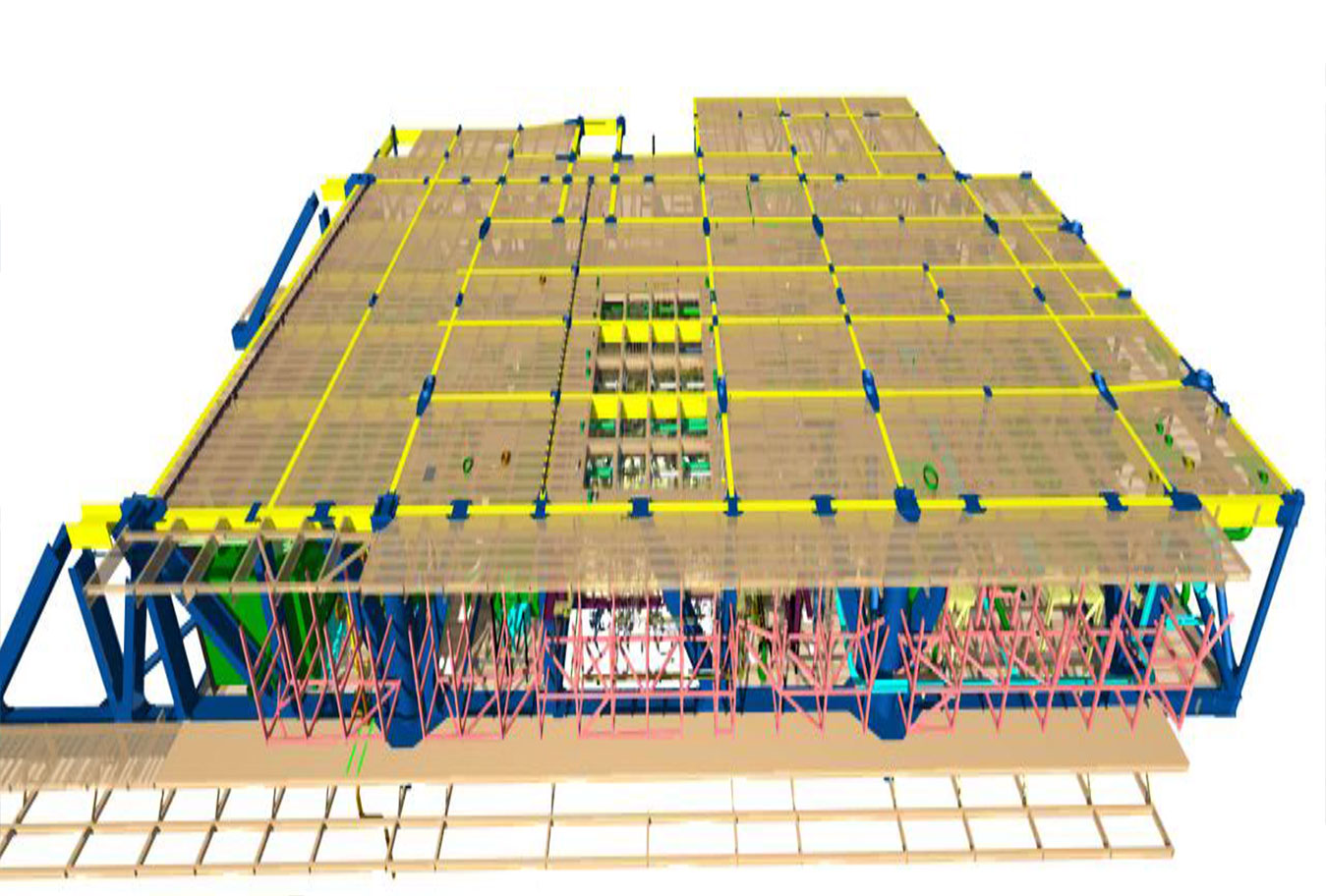

Intermediate Deck

Stacking

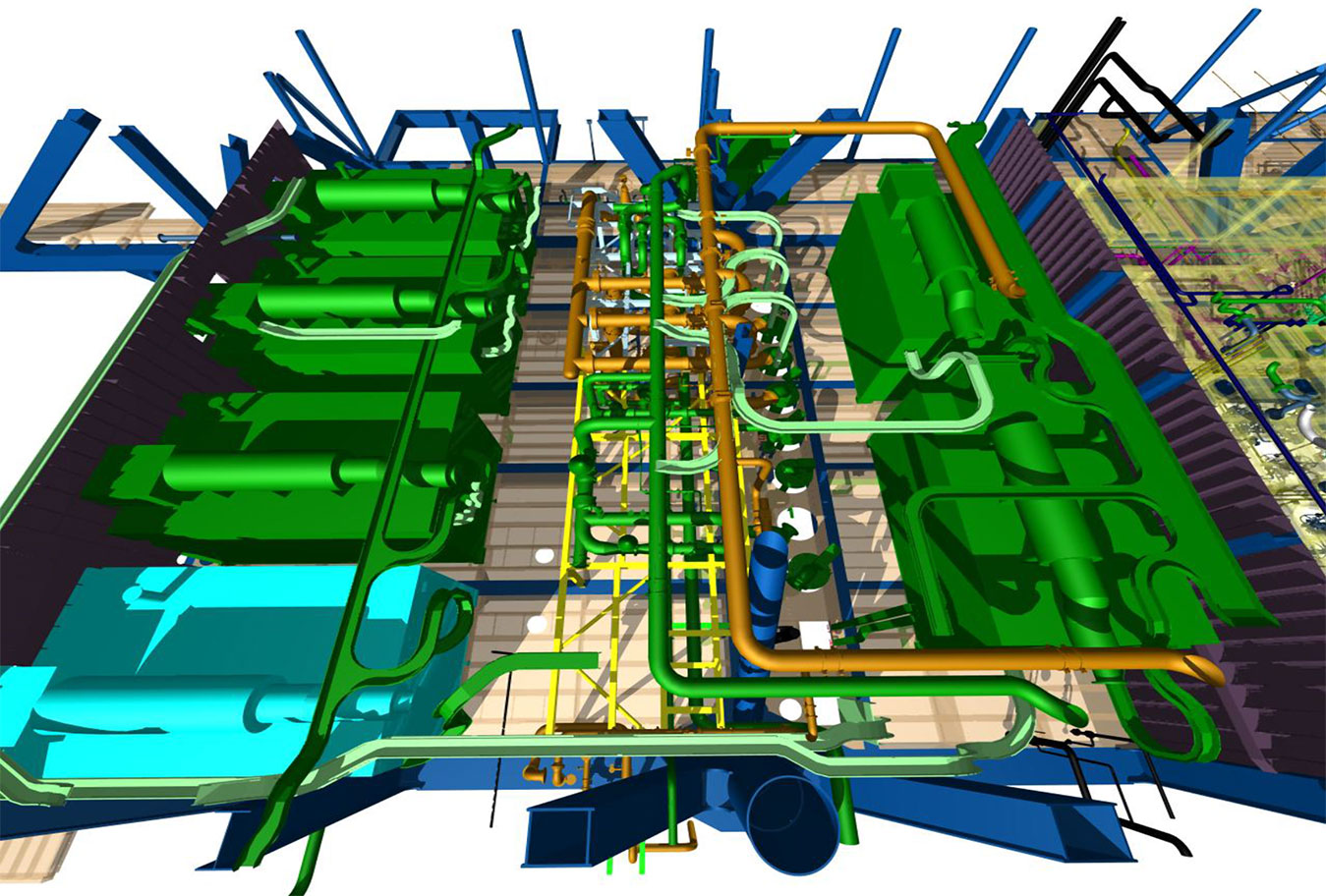

Installation of Equipment, Multi-discipline Activities

Cost Projection

- Approximation of the resources needed to complete project activities.

- Cost estimates for all resources that will be charged to the project.

- Supporting detail must include:

Reference to WBS.

How it was developed?

Assumptions made.

Range of possible results.

Cost Optimisation

- Knowing Budget

- Cost conscious to all employees

- Historical Database

- High volume work front

Expectations- Engineering

- Derived schedule have to be followed

- Support Procurement by raising timely MTO’s

- Long lead items to be raised at earlier stage of project to ensure material availability

- Communication gap to be bridged among multidiscipline

- Deliverables should support Construction sequence

- Prime focus on Yard practices to be given

- Any changes in design should be immediately flagged up to construction during execution phase later comes the paper work

Expectations- Procurement

- Continuous follow up to be made with Engineering for expediting MTO’s

- Challenge Vendors in technical aspects for any delay claim

- Vendor assistance and support at yard to be coordinated in better way

- Alternate supply to be sourced at critical time/ reduce the lead time

- Delivery improvement to be negotiated before PO placement

- Frame agreement to be made in such a way that the terms matches with our process for bulk materials

- Derived scheduled to be maintained at all possible means

- Prioritizing the purchase based on construction sequence

Expectations- Construction

- Standardization of Construction norms for detailed works – System in place to refine the norms

- High speed automation machines – Reduce manpower and skill level requirements

- Improving Erection methods

- Respecting the process duration of E & P and their resource efficiency

- Elite resources – Field of expertise knowledge to be applied in our process to improve competency

- Improvement in Sub Contractor management

- Potential sources to be developed to tackle the crisis scenarios with reasonable expenditure

Monitoring HSE Performances

Rigorous inspection regime

- Daily HSE Inspection and Supervision

- Daily Pre-work Inspection

- Daily Area Manager Inspection

- Daily Joint-Trades Inspection

- Weekly Management Walk

- Weekly PPE Inspection

- Monthly Focus Inspection

Health, Safety and Environment

- Change in approach, from enforcement to advisory

- Good collaboration between HSE and Construction has led to a matured HSE culture within the team

- Implementation of HSE Culture Programs such as Cardinal Rules, PSI and Target Zero Observer has generated more interest within the ground staff

Planning Roles –Procurement

Procurement

- Develop and Maintain Schedule

- Develop Procurement Status Report / Expediting Status Report

- Progress Update

Planning Roles – Mechanical Completion and Commissioning

Mechanical Completion & Commissioning

- Develop Sub-system Schedule based on Commissioning priorities

- Progress Monitoring based on Sub-system activities

- Highlight area of concern and slippages

Conclusion

From PMT

- Project team to have a better control on resource expenditures

- To provide plan/forecast for timely support

To PMT

- To provide one stop solution to PMT so they can concentrate on construction activities

- Minimize external equipment usage

- Capture unbudgeted item and highlight to proposal team